Steam & condensate

A complete range of components for steam and condensate systems – from generation to point of use.

We offer technical advice and flexible solutions tailored to your specifications.

A complete range of components for steam and condensate systems – from generation to point of use.

We offer technical advice and flexible solutions tailored to your specifications.

Automatic discharge of condensate without steam loss.

Inverted bucket, thermodynamic and thermostatic designs to discharge condensate and air while retaining steam.

Pumps condensate without electrical power.

Units for lifting/return of condensate from low points where electricity is undesirable.

Eliminates air and non-condensable gases.

Thermostatic device releasing air/CO₂ at start‑up and during operation to improve heat transfer.

Removes moisture and particles for dry steam.

Cyclone/vortex‑type separator that removes droplets and debris before PRVs and equipment.

Stabilises pressure for safe operation.

Self‑acting or pilot‑operated PRVs for smooth reduction from high‑pressure steam networks to process levels.

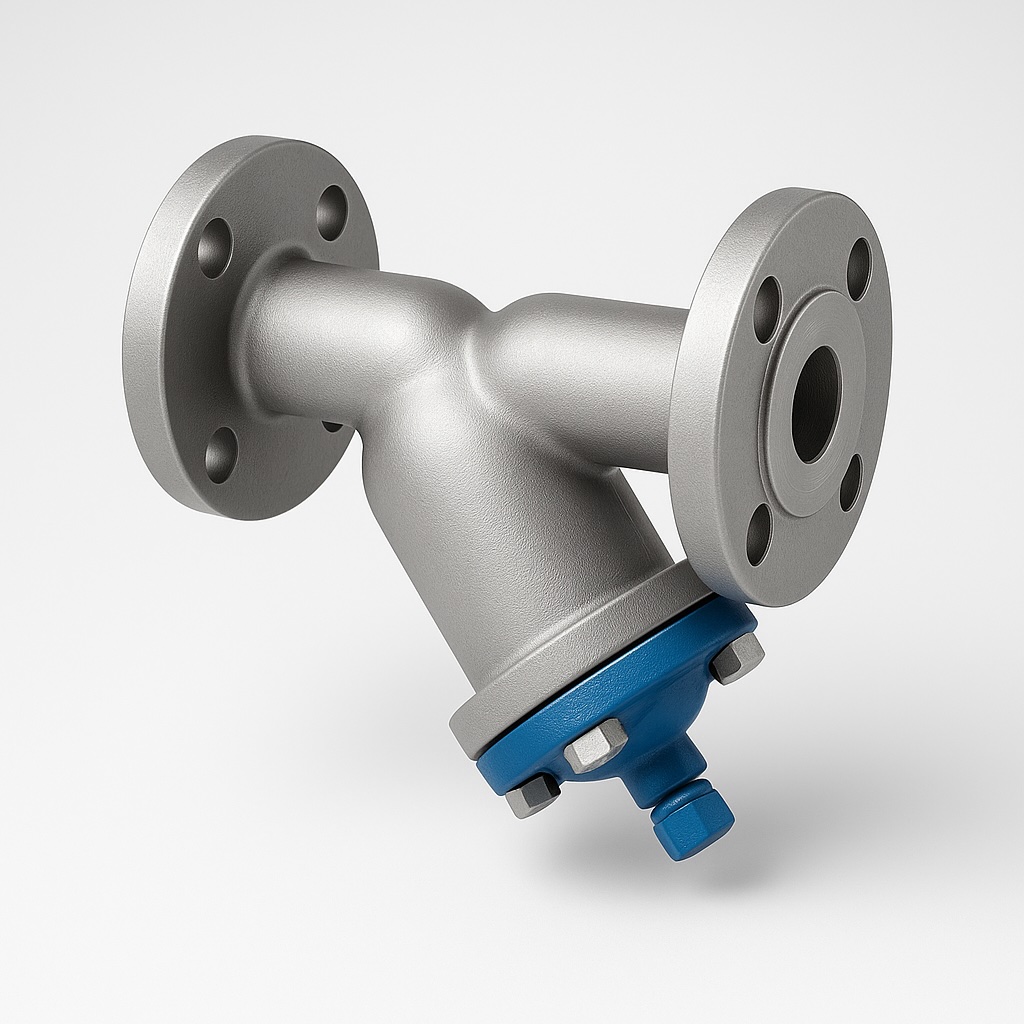

Protects the system from particles and impurities.

Y‑strainers and basket filters; optional drain plugs.

Precise control of pressure and flow.

Single or double‑seated valves with pneumatic/electric actuators for pressure, flow and temperature control.

Opens automatically at overpressure.

Spring‑loaded or lever‑operated valves for rapid pressure relief in boilers and steam systems. Supplied with PED/CE.

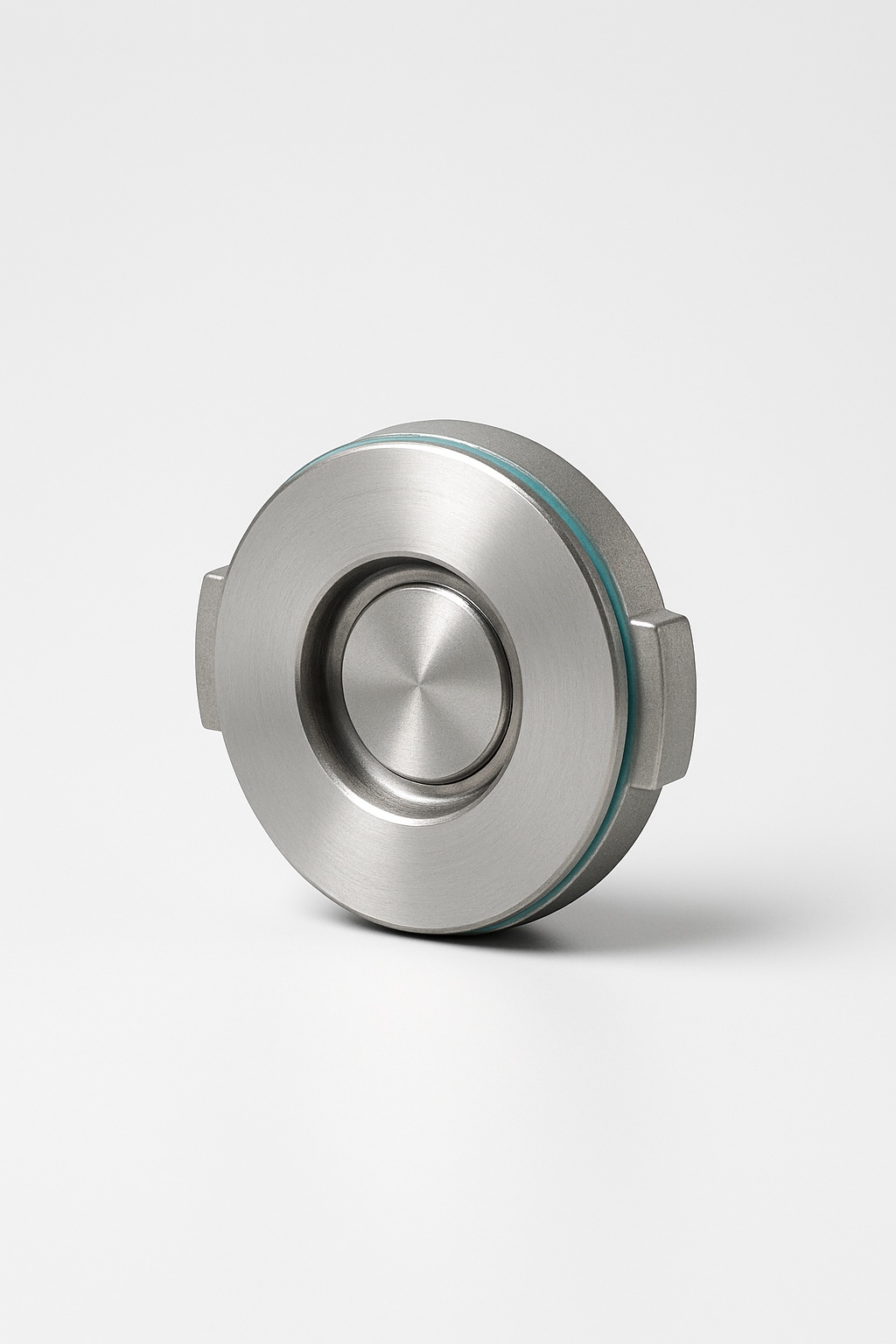

Prevents reverse flow with low pressure drop.

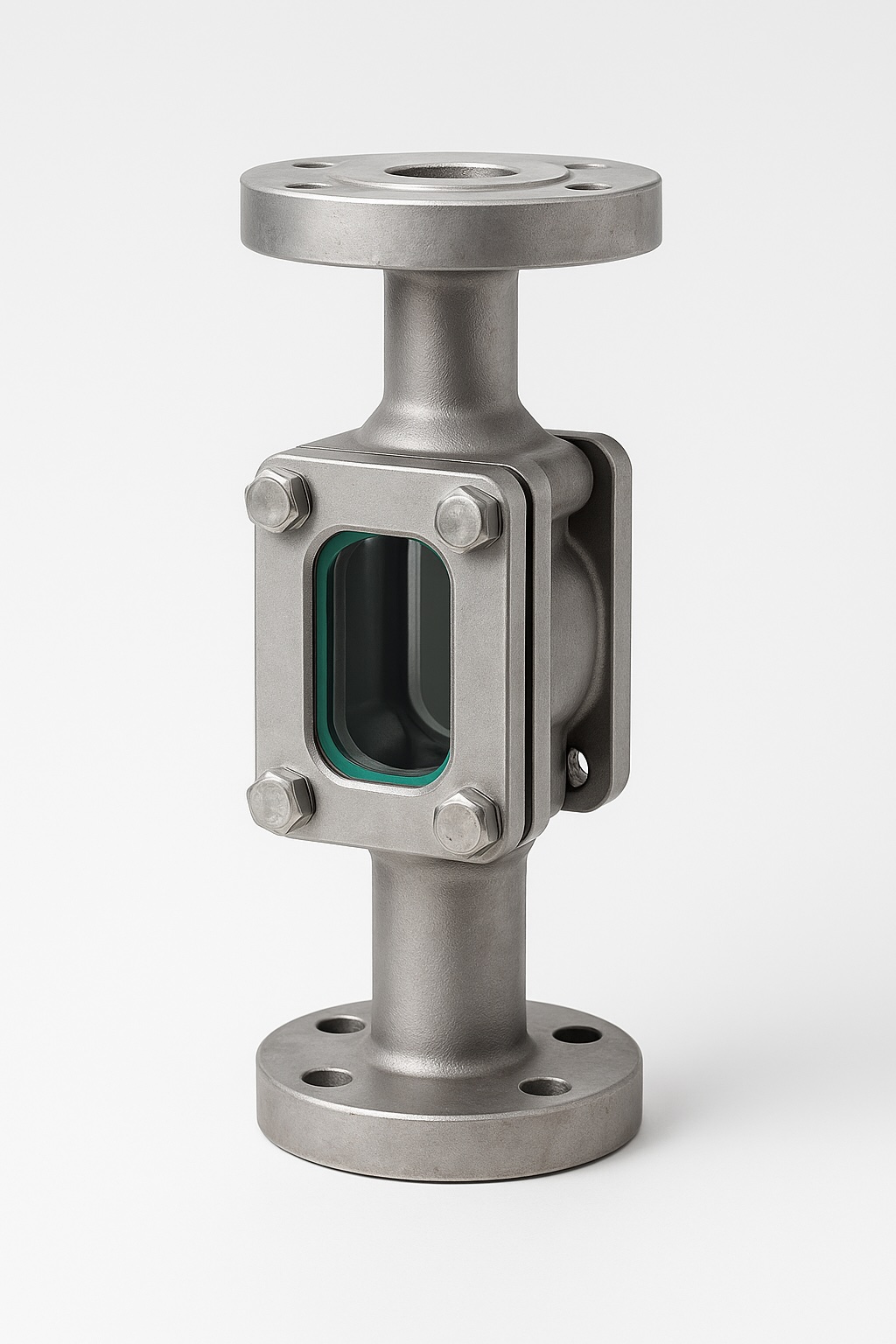

Visual inspection of steam and condensate.

Straight‑through or angle pattern for monitoring flow and trap operation. Toughened/borosilicate glass.

Reliable level indication in tanks and boilers.

Reflex or transparent type with isolation valves and protection glass.

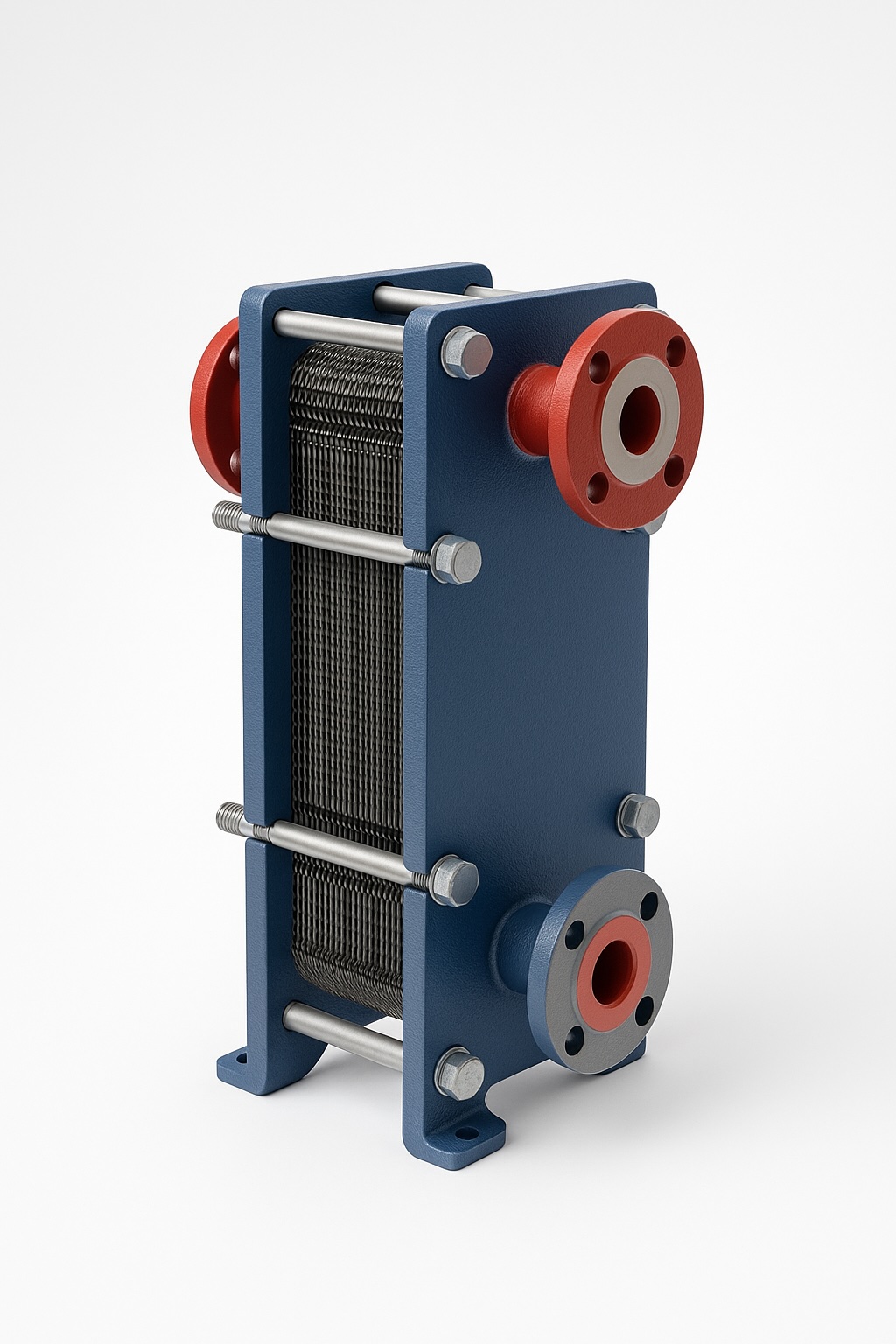

Efficient heat transfer and energy recovery.

Plate and shell‑and‑tube units for recovery and process heating with steam.

Can't find what you need? We offer more models and technical tailoring on request.

Send request